History

In 1889 on the St. Paul bank of the Mississippi River, a small, gray iron foundry was established under the name of its owner, M.V. Johnson. Although records do not tell us the exact size of the original foundry, we know it was a small, wooden structure with cupola melting, similar to all the foundries of those early days. We do know that the location is the same today as then. Records also indicate that it is one of the oldest Twin City area foundries still in operation. Around the time of the First World War, Mr. Johnson sold the foundry to Olaf Krook, who changed the name from Johnson Foundry to Pier Foundry, taking the name from wooden piers left in the river from a failed bridge project.

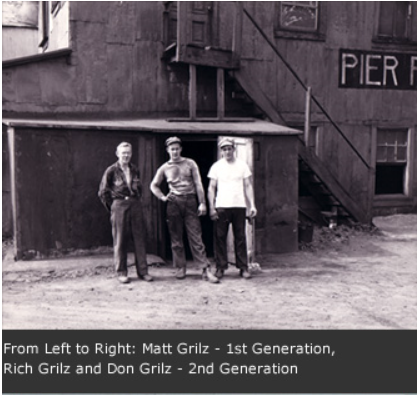

In 1951, the foundry changed hands again to the Grilz family. A young man by the name of Donald Grilz, a pattern maker at American Hoist & Derrick Company, purchased the foundry. Along with his father, Mathias Grilz, Don started production in his new business. After long hours at the “Hoist” (as it was called by locals) Don would join his father and crew of 3 or 4 men, molding and pouring all through the night.

The initial years were an up-hill battle for the small foundry plagued by floods, fire and labor disputes. But, Don and his father were determined, and that determination saw them through the adversity of the early years. Pier Foundry continued forward adding space and upgrading equipment to handle the needs of the growing customer base. Nearly a century after its birth, the largest expansion and modernization took place with millions of dollars invested in new production areas and new production equipment.

Today Pier Foundry is one of the most efficient, and modern jobbing shops in the Upper Midwest. With the addition of electric melting, automatic molding and material handling, Pier Foundry has progressed from a small stove grate foundry at the turn of the last century to the highly automated production foundry it is today.